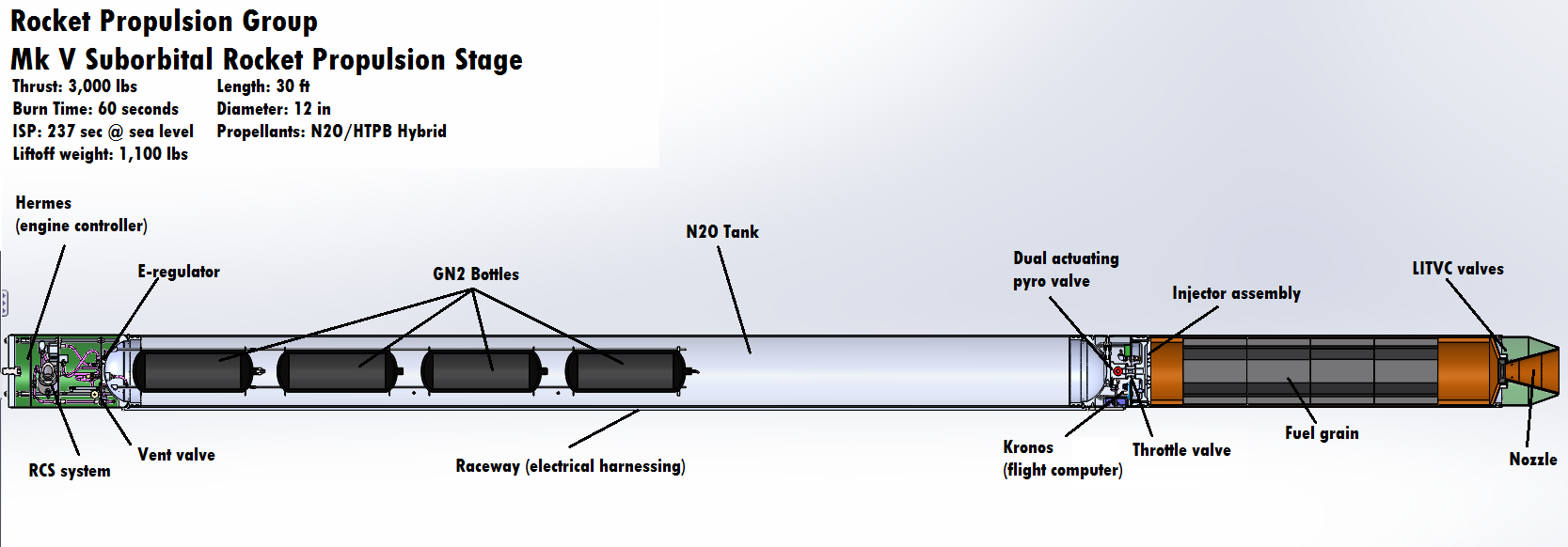

Kronos (Hybrid/ Mk V)

Kronos’ duties consist of being a communication node, as well as system monitoring, data logging, combustion control, and in-flight algorithmic computation. The brains of Kronos are a 168 MHz ARM Cortex-M4 microcontroller. The Cortex-M4 is special because it has a hardware FPU which allows us to use a single processor for our math and command and data handling.

For data monitoring, Kronos is equipped to monitor seven thermocouples, placed at critical areas on the rocket and its tanks to measure the temperature of the nitrous oxide and the engine temperature. Kronos also monitors the pressure transducers in the combustion chamber and manifold, and they are read into a high-resolution 24-bit delta sigma ADC. There is also a six degrees of freedom high-resolution factory-calibrated inertial measurement module on board aligned with a pre-defined axis on the rocket. All data is logged to a 128 megabit solid-state NOR flash memory module, along with the data collected from Hermes.

As a combustion controller, Kronos has 6 electric match channels, and can sense the resistance of these e-matches within 10 mOhm, to determine whether there is a closed or open circuit on the ematch channel. This is important because we cannot visually confirm our ematches after installation. There are 3 channels, all with redundancy, because this is a critical function of the rocket.

Kronos also serves as the central hub of for communication with the other board on the rocket, and as such serves as the main flight computer. It has two RS-422 communication interfaces, one to the ground support electronics and one to its sister board, Hermes. The RS-422 communication uses a proprietary protocol and utilizes a modified cat5e cable. Kronos therefore acts as the rocket’s communication node, allowing Hermes and the GSE to exchange information. In addition to the two RS-422 lines, there is a micro-usb debug port which presents a command shell in which the user can monitor the system in media res. This port is also be used to inject data from our real time computer simulations and emulate the entire flight from take-off to recovery in the lab for our hardware-in-the-loop testing.

Finally, Kronos also controls 5 valves, which are all actuated by servos. One servo is for throttling the thrust of the engine, while the other 4 are for two-axis liquid injection thrust vectoring control, how Starscraper steers itself and stabilizes its flight without using any external fins.